Let us take you on a tour of the processes by which we deliver safe, hygienic products to our customers.

In order to meet customers’ needs, we use the optimal washing method for each product type and material.

By introducing state-of-the-art equipment, we have achieved energy-saving automation of every process from receipt of the load to washing, drying, finishing, quality control and dispatch.

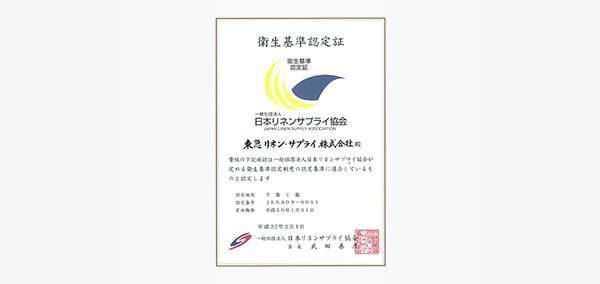

In addition, we give consideration to the global environment as well as our immediate surroundings by utilizing exhaust heat to reduce fuel consumption and by recycling wastewater.

The workflow in the factory is geared to streamlining the work involved in each process and improving the quality of our products.

About Tokyu Linen Supply factories

We have factories in Kanagawa, Chiba, Shizuoka and Tochigi Prefectures. Our Chiba factory has acquired the Hygiene Standard Certificate issued under the Hygiene Standard Certification System* established by the Japan Linen Supply Association. Much of the equipment used at the factory is equipped with inspection cameras that contribute to improving the quality of our products.

Our Sano factory in Sano, Tochigi Prefecture, came on line in July 2018 and is our first new factory in almost 30 years. As well as introducing state-of-the-art equipment and delivering high quality products to customers, the factory aims to provide an employee-friendly working environment.

* The Hygiene Standard Certification System is important for ensuring the quality of linen supplies. It specifies the obligation to acquire national qualifications at managerial level, items related to hygiene, and detailed methods of sterilization. About 76 facilities nationwide are currently certified (as of March 2018).

Flow from collection to dispatch

The linen is retrieved from the automated warehouse and sent to the sorting system.

The sorted linen goes into bags suspended below floor level and is transported automatically to the tunnel washer.

When its turn comes, the linen goes into the tunnel washer.

A different detergent is used for each type of linen.br>

Whites, colors and type of soiling are checked to determine the type of detergent to be used.br>

The tunnel washers are equipped with automatic detergent dispensers to speed up the washing process.

A batch washer is used for any linen that needs to be rewashed.

The water is extracted from the washed linen by applying pressure using an extractor.

The linen is then carried by conveyor to the dryer.

Drying time varies depending on the type of linen. For example, towels must be completely dry, whereas sheets and pillowcases must be only half dry.

This is because when sheets are completely dry, it is difficult to remove the wrinkles even with the roller ironer. By leaving them half-dry, the wrinkles are removed by the ironer.

After drying, the linen is put into bags and sent to the finishing zone.

- Sheets

- Towels

- Yukata (cotton kimono) and bath robes

- Pillowcases

When the sheets come out of the dryer, they are untangled by an “untangler” and transported to the operator by conveyor.

The sheets are spread out by the machine which shakes them sideways, then they are fed onto the roller ironer.

After passing inspection by the inspection machine, the sheets are folded and automatically sorted into piles by size.

If the inspection machine detects any soiling, tears, etc., the sheets are removed from the line without being folded.

Any soiled or torn towels are removed from the line by the double-sided inspection machine.

The towels are counted by the machine and when the set number of towels is reached, the folded towels are automatically ejected.

The towels are then carried by conveyor to the metal detector and tied in bundles.

The robes are hung on the machine’s hangers and hung on the hanger rail which is automatically sent to the tunnel finisher.

After the wrinkles have been removed by the hot air inside the tunnel, the robes are folded by a folder.

There are two ways of folding the robes: “collar outside” (with the collar showing) and “collar inside” (with the collar folded inside).

When the pillowcases exit the dryer, they are untangled by an untangler and transported to the operator by conveyor.

After the corners have been lightly shaken out, the pillowcases are fed onto the roller ironer.

After passing through the double-sided inspection machine, they are folded.

Like the other products, any pillowcases with tears, soiling, etc. are rejected.

Sterilized containers are used in the dispatch zone.

All products pass through the metal detector before being tied in bundles and loaded in the containers.

The load data is saved and the containers are sent to the automated warehouse for outgoing products.

The products are then dispatched sequentially for delivery to the customers.

Quality Control

-

Hygiene Standard Certificate and clean/semi-dirty work zones

The Hygiene Standard Certificate is only issued to factories that have acquired certification under the Hygiene Standard Certification System established by the Japan Linen Supply Association. The criteria are wide-ranging. For example, “Demarcation of clean and semi-dirty work zones” requires that the clean zone for washed linen must be separated from the semi-dirty zone for unwashed linen by a 180cm-high wall. This standard was set to ensure that unwashed linen and washed lined do not get mixed up. (* Our Chiba factory has acquired the Hygiene Standard Certificate and the Sano factory is working toward acquisition.)

-

Inspection equipment

The inspection cameras detect soiled or torn linen, etc. that is unsuitable for delivery to customers. The cameras capture both sides of the linen and detect four items: soiling, tears, wrinkles and defective shape.

-

Automated warehousing

Automated warehousing is used for receiving and dispatching supplies.

When linen arrives at or leaves the warehouse, the data is saved to ensure that the number of items in the factory can be determined at all times. -

Container sterilization

After the containers are emptied, they are sterilized to keep them in a hygienic condition.

After sterilization, they are automatically sent to the product loading zone. -

Bag system

Loads are retrieved from the automated warehouse as required and sent to the sorting system.

The sorting system sorts the used linen into the dirty linen bags suspended below floor level.

The bags are then automatically emptied into the tunnel washer in turn.

After the linen automatically exits the dryer, it is put into the clean linen bags and sent to the finishing zone. -

Detergent (controlled by computer, not manually)

As different kinds of detergent are used in the tunnel washers for different kinds of linen, detailed settings are required. Automatic detergent dispensing, rather than manual dispensing, enables us to provide stable product quality.

-

Conveyor system

After finishing by the roller ironer, the linen is folded by the folder and placed on the conveyor to be sent automatically to the loading zone.

The products are not handled, thus saving manpower and maintaining the products in a hygienic state.

Safety Measures in the Factory

-

Air conditioning

The air conditioning system in the Sano factory utilizes the abundant supply of groundwater.

Air conditioning efficiency has been enhanced by providing a wall between the heat generating equipment and the workers.

In addition, mist is used to lower the temperature on the factory floor and prevent static electricity in winter. -

Induction fans

Our Chiba and Tokai factories are equipped with induction fans.

The fans control the air flow to lower the room temperature by around 3.5°C. -

Safety fences

When the safety fence around a machine is opened, the machine stops automatically.

-

Corner mirrors

Mirrors are provided at corners and blind spots to prevent collisions.

Environmental Measures

-

Wastewater recycling system

Instead of discharging the water used in the factory, 75 – 80% of the wastewater at our Chiba factory is treated and recycled.

-

LED lights

LED lights are used in the factory to provide a bright working environment while saving energy.

-

Flash steam generating system

We have installed a system for recovering and reusing the steam used in the production process instead of just discarding it, thus enabling efficient energy use as well as reducing fuel consumption by the boilers.

-

Heat exchanger

(Exhaust heat is recycled by heat exchange from wastewater)Passing groundwater through the (warm) washing water that is discarded after extraction reduces waste of thermal energy as well as producing warm water.